The predecessor of the TECHNOPLAST Group was established in 1980 under the name GAM GM, a company constituted under civil law; this was among the first private industrial enterprises in Hungary. Later on, when the opportunity presented itself the company was transferred to a GMK (special form of partnership in the late 80’s in Hungary).

In the beginning the company operated as an engineering office; designing machinery, preparing manufacturing technologies and providing other engineering services. Within a year counted from foundation tool production was added to our activities: we primarily specialized in the manufacturing of plastic injection moulding tools for the household, cosmetics and pharmaceutical industries.

Our company started to manufacture injection moulding tools suitable to produce engineering plastics principally for the automotive industry; this was the time when we changed the name and legal form of our company to TECHNOPLAST Bt. (unlimited partnership) that represented our activities better.

From 1993 we were first level suppliers of one of the biggest automotive firms in Hungary, RÁBA Rt, for more than fifteen years. We mainly supplied forging tool sets and different appliances. We transformed our company to TECHNOPLAST McD Kft. (limited liability company) in 1995 and the main activities became tool and component manufacturing.

In 2000 we established a joint venture with the British centre of the Japanese ARRK for the manufacturing of prototype plastic injection moulding tools under the name ARRK-TECH Kft, which operated successfully for four years.

We started to produce rapid prototyping parts and became involved in 3D SLA printing, vacuum and RIM casting in 2000. The equipment and process knowledge was provided by the German ALPHAFORM AG. Initially this activity operated as one of the workshops of the enterprise but the increase of the number of employees and the revenues as a result of the increased demands justified that the activity was organized into an independent venture. This happened in 2005 under the name of TECHNOPLAST PROTOTYPING Kft.

We organized our ventures with different types of activities into one company that operates in its present form close to the city of Miskolc, in the Felsőzsolca Industrial Park since 2011, under the name TECHNOPLAST GROUP Kft.

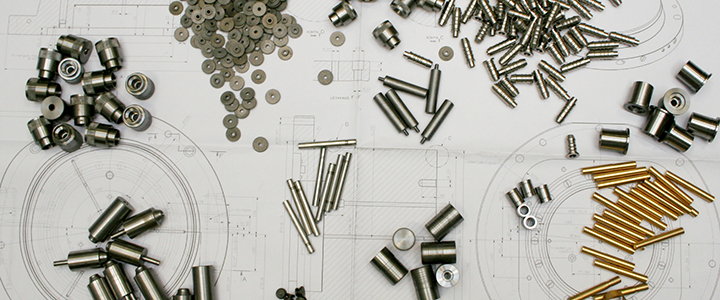

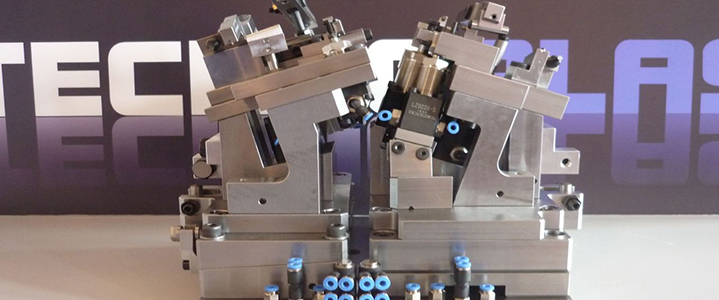

Machine industry

Designing and producing components of general purpose, using CNC and CAD/CAM technology, in non-series, small and large series: machining of steel, stainless steel, hardened steel, titanium, INVAR, hard metal, copper, brass, aluminium, aluminium alloy etc. materials by using 3-4-5-axle CNC milling machines, CNC lathes, sinker and wire electric discharge machines (EDM) as well as 3D measuring machines.

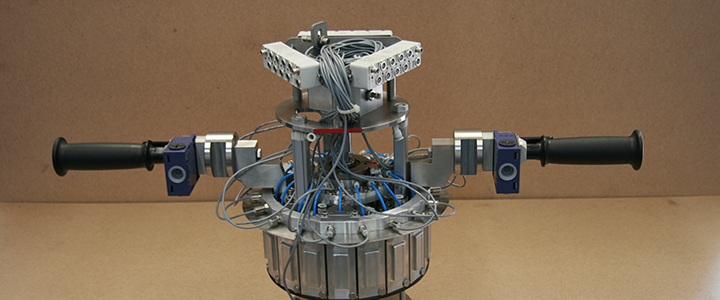

Manufacturing plastic components with 3D printing, rapid prototyping processes, injection moulding, (you can read more about them here). Assembling subassemblies from plastic and metal parts and manufacturing complex machines.

Automotive industry

Manufacturing of plastic and rubber interior and exterior parts as well as parts in the engine compartment, non-series and in small series, by applying rapid prototyping processes (3D printing, vacuum-casting, RIM casting); in medium series by injection moulding in plastic or Al-Bz inserts in soft tools; in large series with automatic hardened tools. If required we can paint the parts in accordance with the quality standards of the automotive industry.

Our goal is to satisfy customer requirements ranging from one piece to series of million pieces, applying the most efficient technologies (you can read more about them here).

Complete operating units are assembled from the parts. (E.g. passenger car A/C equipment).

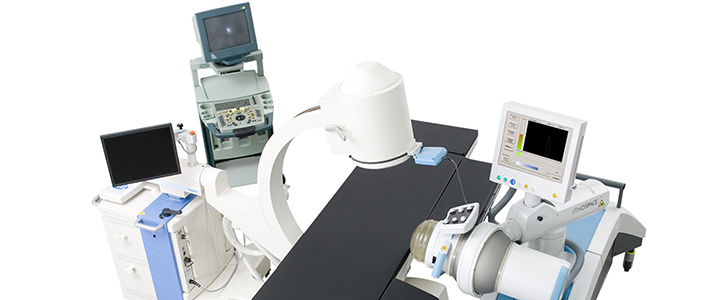

Manufacturing of medical instruments

We are reliable suppliers of domestic, Swiss and German companies manufacturing medical devices, medicinal products, pharmaceutical manufacturers and cosmetic firms since 1985. We prepare complete equipment, subassemblies, casings, various plastic and metal parts as required by our customers. We also produce unique, small and large series pharmaceutical products. If required, we participate in product development and prototype manufacturing. We mass-produce complete, assembled lithotripters for which the electronics are made by our German partner.

Aeronautical industry

We are supplying tools, devices, GO/NOGO measuring instruments for machining, welding, soldering, assembling and inspecting gas turbines and other parts to French aeronautical companies for more than six years.

References: SAS Malichaud Atlantique France, Chromalloy France, Sarl Soudax Equipments France

Space industry

Regarding the space industry we produced baffles, heat protection elements, supports and heat shields for the different types of the Sentinel 2 satellites.

Within the frame of the FOCUS project of the European Space Agency we have manufactured the mechanical components of an experimental instrument. The instrument was tested on the International Space Station.

Customer: Admatis, ESA, EADS Astrium GmbH.

Quote request

Our usable service is only a few aroused your interest, request a quote and a staff member will contact you soon.